Till now we can see What is a PLC System? How does PLC work? in my previous articles. We have also seen various free tutorials of the PLC system, such as,

- What is PLC? How does it work?

- Sinking and Sourcing Circuits.

- Logic Gates using PLC Ladder logic.

- 5 different types of PLC programming languages.

- Electrical motor starter with a PLC program.

- 20+ Arithmetic instructions in PLC Programming.

- Basics of PLC Timer instructions.

- Types of PLC Counter in PLC Programming.

- Different Types of Siemens PLC Programming blocks.

- 30+ Most useful PLC Communication Protocols.

- Converter instructions in PLC Programming.

- Analog Scaling and Unscaling in PLC Programming.

- Difference between FC and FB in Siemens PLC.

- What is memory in Siemens PLC?

- Top PLC Manufacturers: PLC Brands and Ranking.

In this article, we are going to see what is a plc rack or plc chassis?

Table of Contents

What is Rack and Chassis in PLC System?

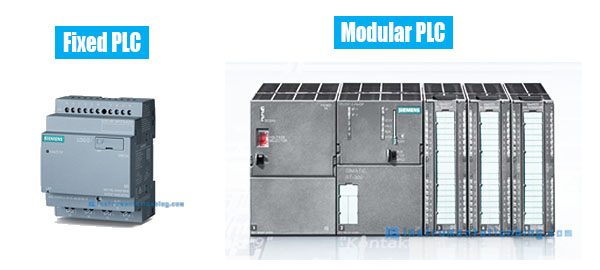

Generally, in the industries, we can find mainly two types of PLC system: Fixed PLC and Modular PLC.

Modular PLC is mostly used in industries because it can provide flexibility to increase the IOs.

What is a PLC Rack?

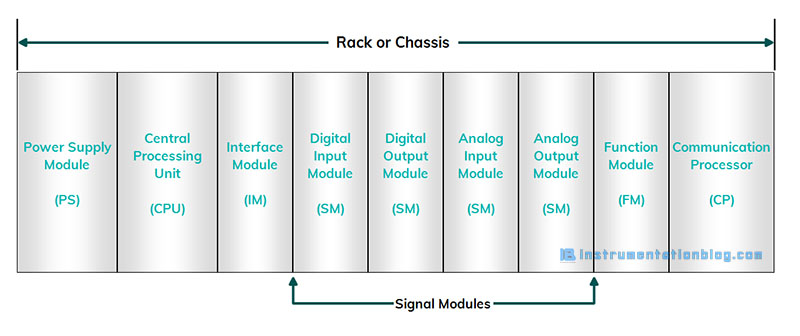

The rack serves as the backbone of the modular PLC system that holds all the modules together such as CPU, Power Module, Communication Module, Input-Output Modules, etc. PLC Rack synchronizes both the power and communication signal to all the modules.

A PLC Rack can be of different sizes and shapes depending upon the requirement of the control system.

You can see the different modules are fitted in the same rack or chassis of the modular PLC system in the below diagram.

There are multiple input and output modules are plugged together in the same rack of the modular PLC system. The power supply module is plugged into the plc rack which regulates the required amount of power to all the modules.

What are the types of PLC Rack?

Depending on the requirement, the PLC systems have racks of different sizes and shapes.

The one system which has a stackable style, in which Power Supply, CPU, IO Modules, etc. are separate. But they are all connected with connectors built to attach all the components together.

They all are connected in a continuous data bus throughout the system. This internal data bus is often referred to as the PLC backplane. This type of PLC backplane is often referred to as the “passive backplane”.

Another option is a separate base unit that holds all the modules. Each module will seat in a particular slot in the base unit. In this type of system PLC backplane is already installed in the base unit. This type of PLC backplane is often referred to as the “active backplane”.

The base unit comes with different numbers of slots and some base unit has a built-in power supply connected with it.

What is the difference when it comes to change the module in the active backplane and passive backplane?

The main question from the maintenance point of view is that How easy to change the module? In a stackable style or passive backplane PLC system, you need to break the data bus while changing the module.

But in an active backplane PLC system, it is very easy to change the module. It just simply slides out to remove the module and slide in to insert the module.

What is the purpose of the rack and chassis in the PLC System?

The main functions of the rack or chassis in the PLC system are

- It distributes the power supply evenly.

- It houses different input-output modules.

- It acts as a communication link between the CPU and different modules.

You can read more articles about Electrical and you can also find books that boost your knowledge in the field of Instrumentation ⇒

Thanks for Reading!