Table of Contents

How does an Ultrasonic Level Transmitter work?

An ultrasonic level transmitter is a non-contact type of level transmitter. Ultrasonic level transmitter is used for continuous level measurement in many industries. An ultrasonic level transmitter is the best choice for the measurement of water level in open sumps.

The ultrasonic level transmitter is mounted on the top of the tank whose level measurement is needed. Ultrasonic waves are transmitted from the ultrasonic level transmitter. These ultrasonic waves hit the top of the material in the tank. After hitting the material, the waves travel back to the transmitter. The transmitter has a microprocessor that calculates the time taken by the ultrasonic waves to go and come back.

Using a simple formula of distance i.e.

Distance = (speed of ultrasonic waves * time taken) / 2

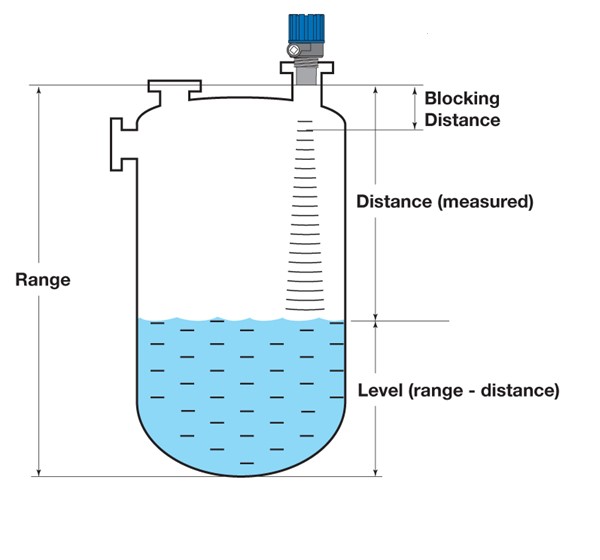

We get the distance between the ultrasonic level transmitter and the material. In every ultrasonic level transmitter, a blocking distance parameter is entered. This blocking distance is nothing but the short range near the transmitter which the transmitter will not consider if waves come back from this distance. Another parameter named tank height is entered in the configuration.

From the figure,

Range = Distance + Level

The range is known quantity. Distance is calculated by the ultrasonic level transmitter using speed = distance/time. Hence, we get the level measurement. This all process is done inside the ultrasonic level transmitter using a microprocessor itself.

The ultrasonic waves are produced by a piezoelectric crystal. This piezoelectric crystal receives electrical energy as input and gives output as ultrasonic waves. Various frequencies of ultrasonic waves are produced by these piezoelectric crystals. The range varies from 15 to 200 kHz. The ultrasonic waves are nothing but a kind of mechanical wave.

These waves require a medium for traveling. So, we can use the ultrasonic level transmitter in tanks where the medium is air or pressurized medium. We cannot use the ultrasonic level transmitter in applications where the medium is the vacuum. Because ultrasonic waves cannot travel in a vacuum. Mostly you can see a majority of ultrasonic level transmitters in Effluent Treatment Plants for measurement of water level in sumps.

Advantages of Ultrasonic Level Transmitter

- Level detection without physical contact with the medium is possible in an ultrasonic level transmitter

- It has a large measuring up to 6 meters

- This type of transmitter can detect a variety of objects like liquid level, solid level, foam level, and many more

- As there is no moving part in an ultrasonic level transmitter, they are almost maintenance-free.

- Configuration of ultrasonic level transmitters is very easy. Only a few parameters like tank height, blocking distance, and damping are essential for the basic functioning of this transmitter.

- The cost of ultrasonic level transmitters is low compared to that of other non-contact type level transmitters like radar type level transmitters.

Disadvantages of Ultrasonic Level Transmitter

- We cannot use an ultrasonic level transmitter in vacuum service. This is because ultrasonic waves are a kind of mechanical waves and they require a medium to travel

- The ultrasonic transmitter cannot be used in mediums that absorb the ultrasonic waves.

- Change in temperature cause change in the speed of the ultrasonic waves. Hence, we will also get a change in the height obtained. So, temperature compensation is must required.

- The ultrasonic level transmitter cannot be used in high-temperature service. Because the sensor is made up of a kind of polymer only.

- Sometimes, moisture droplets get attached to the sensor tip. Because of this ultrasonic level transmitter starts showing 100% level. Hence removing the ultrasonic level transmitter and cleaning the ultrasonic level transmitter becomes necessary.

Applications of Ultrasonic Level Transmitter

- Food & Beverage industry

- Chemical industry

- Tank water level measurement

- Open tank level measurement

Must-read articles,

- What is PLC? How does it work?

- What is a Pull Cord Switch?

- What is a Belt Sway Switch?

- Closed-loop vs Open-loop

- What is PID Control?

- PLC Programming Blocks

Interview-related articles,

You can read more articles about Instrumentations and find the books that boost your knowledge in the field of instrumentation ⇒