Table of Contents

What are Capacitive Proximity Sensors?

Proximity sensors are used in many industries to detect the presence of an object without being in physical contact with it. They are commonly referred to as non-contact sensors. They are highly useful for working with delicate or unstable objects which could be damaged by contact with other types of sensors. Common proximity sensor types include photoelectric, capacitive, and inductive.

Operation of Capacitive Proximity Sensor

Capacitive proximity sensors work similarly to inductive proximity sensors, the main difference is that it produces an electrostatic field instead of an electromagnetic field. The capacitive proximity sensor will sense metallic as well as non-metallic materials such as plastic, paper, glass, liquid, and cloth.

As the name suggests capacitive proximity sensors operate by noting a change in capacitance between the sensor’s sensing surface and a sensing object. The amount of capacitance mainly depends on the size and distance of the sensing object.

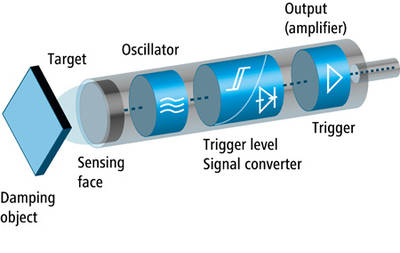

image reference from motioncontroltips.com

Working Principle of Capacitive Proximity Sensor

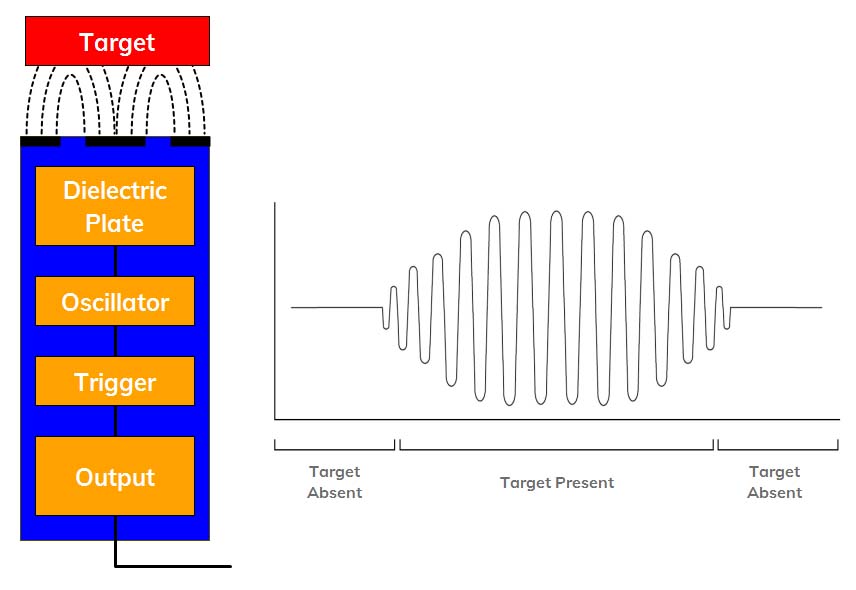

The capacitive proximity sensor has a high-frequency oscillator along with a sensing surface formed by two concentrically shaped metal electrodes of an unwound capacitor. When an object comes near the sensing surface it enters the electrostatic field of the electrodes and changes the capacitance in an oscillator circuit.

As a result, the oscillator starts oscillating, and a trigger circuit reads the oscillator amplitude. When it reaches a certain amplitude it will change the status of the sensor output. As the object moves away from the sensor, the oscillator amplitude decreases, it switches the state of the sensor output to its original state.

The capacitive proximity sensors have a sensing range from a few millimeters to about an inch. The capacitive proximity sensor detects the larger dielectric constant of a target easily. This makes possible the detection of materials inside nonmetallic containers because the liquid has a much higher dielectric constant than the container, which gives the sensor ability to see through the container and detect the liquid.

Advantages of Capacitive proximity sensors

- Non-contact type detection

- Materials such as plastic, paper, liquid, glass, or metal can detect

- Able to detect objects through non-metallic walls with its wide sensitivity band

- Well-suited for the industrial environment

- Contains a potentiometer that allows users to adjust sensor sensitivity, such that only wanted objects will be sensed

- No moving parts, ensuring a longer service life

Disadvantages of Capacitive proximity sensors

- Relative low range, though incremental increase from inductive sensors

- Higher price as compared to inductive sensors

Must-read articles,

- What is PLC? How does it work?

- What is a Pull Cord Switch?

- What is a Belt Sway Switch?

- Closed-loop vs Open-loop

- What is PID Control?

- PLC Programming Blocks

Interview-related articles,

You can read more articles about Instrumentations and find the books that boost your knowledge in the field of instrumentation ⇒