Table of Contents

What is a Servo Motor? How its work?

We have seen the working of robotics arms in many industries and most of us thought that how these arms move very precisely. We often see printer printing a paper and see the accurate movement of the printing head on the paper to write or draw.

There are plenty of other applications like automatic door opening/closing, antenna positioning, solar panel movement, etc. In all these applications one thing is common that the precise and accurate linear and angular movements. Servo Motors are the perfect mechanism to achieve these accurate movements.

So, in this article, we are going to see What is a Servo Motor? How does it work? Types of Servo Motors and Applications where it is used.

What is a Servo Motor?

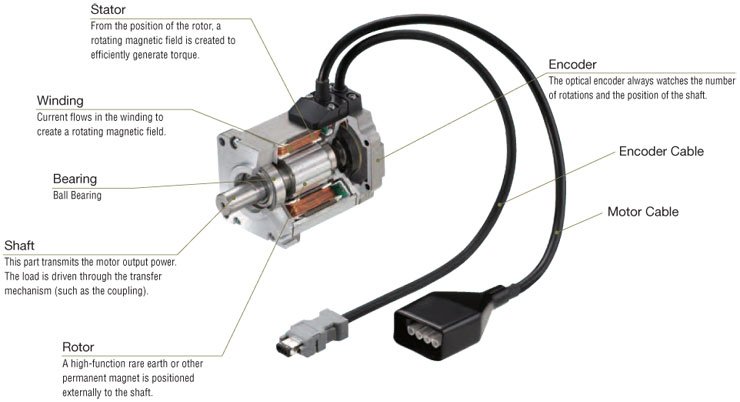

A servo motor is an electric motor that can rotate with great precision and high efficiency. Basically, the Servo motor is a part of a closed-loop system. This system comprises several parts such as

⇒ AC or DC Motor

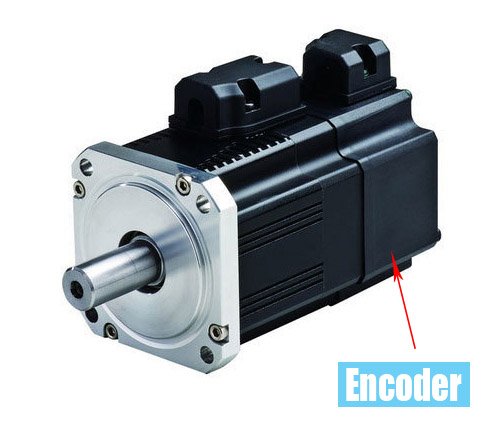

⇒ Position feedback device like Encoder

⇒ Gear Box Assembly to reduce motor speed

⇒ Control Circuitry

image reference from orientalmotor.com

Working of a Servo Motor

The servo motor utilizes a regular AC or DC motor couples with a position feedback device. The output shaft of the motor is connected with gear assembly to reduce the speed.

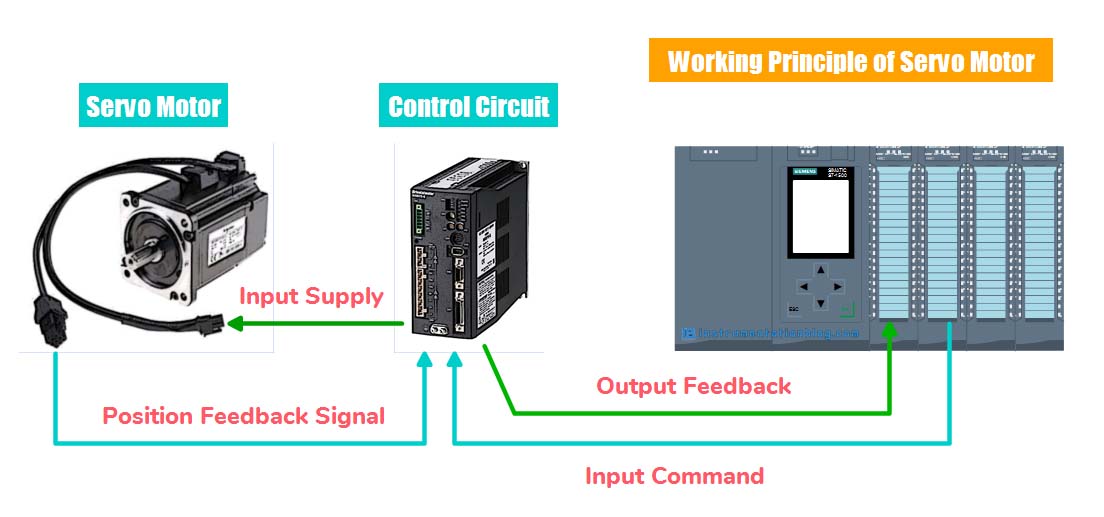

The control circuit is an important part of the servo motor. Servo motor works in a closed-loop system which receives a signal from the controller either in analog or digital and controls the amount of movement.

The position feedback sensor senses the position of the shaft and gives feedback to the controller.

Types of Servo Motors

The servo motor is mainly classified into three categories, such as

1st. AC Servo Motor or DC Servo Motor

In AC servo motor speed is directly proportional to the frequency of the supply voltage and the number of magnetic poles, while in DC servo motor speed is directly proportional to the applied voltage.

AC servo motor has certain advantages over DC servo motor such as,

⇒ It is more efficient than a DC servo motor because of its unique speed to torque handling capability.

⇒ It is less noisy than the DC servo motor.

⇒ It is available in a vast range of shapes and sizes.

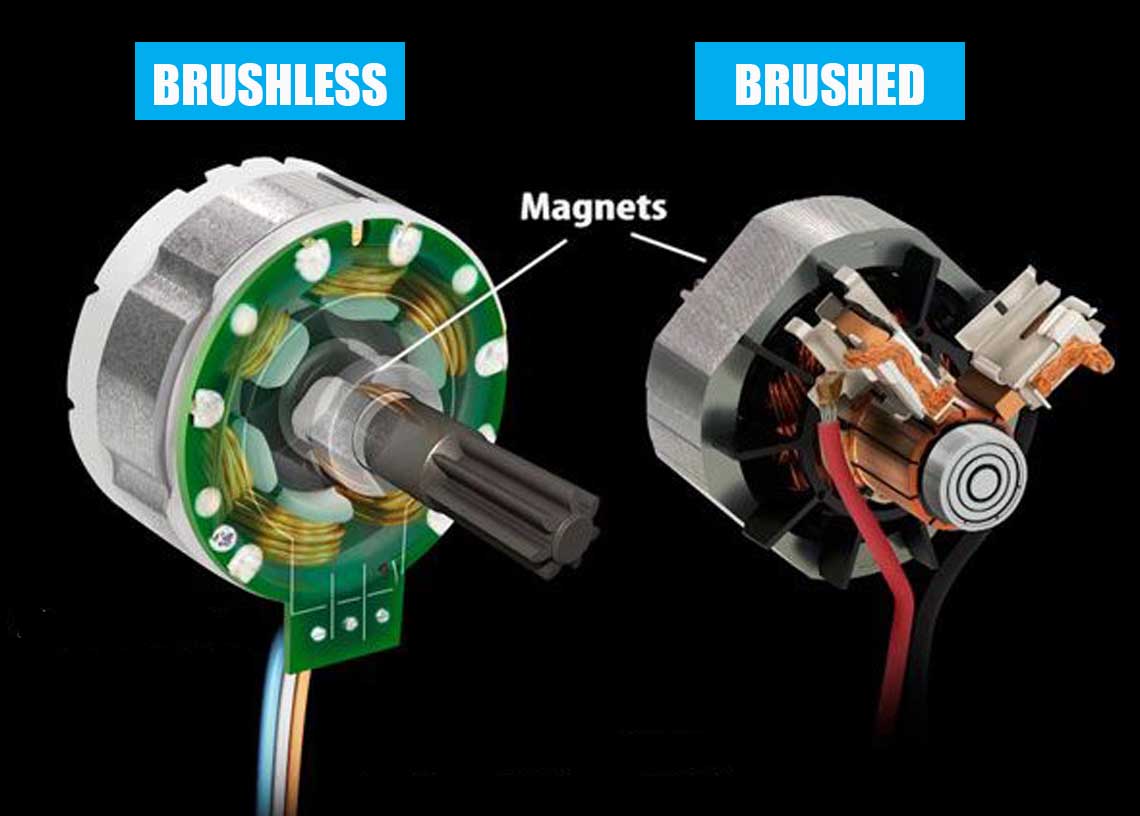

2nd. Brushed or Brushless

In a DC servo motor, commutation is achieved using mechanically with brushes or electronically without brushes.

Brushed motors have windings in the rotor and a permanent magnet in the stator. Brushed motors are simpler in design, easily installed and operate and low in cost.

Brushed servo motors require higher maintenance due to the regular wear and tear of carbon brushes. It is bigger in size and generates an adequate amount of noise while in operation.

image reference from rozum robotics

Brushless motors have windings in the stator and permanent magnets attached to the rotor. Brushless motors provide higher output, higher torque, and compact in size.

It requires lower maintenance due to the absence of carbon brushes and generates low noise.

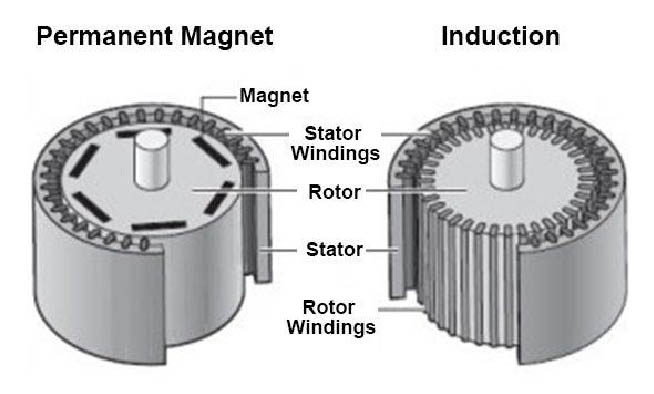

3rd. Synchronous or Asynchronous

Synchronous and Asynchronous is a term that is related to speed. AC servo motors are often categorized based on the speed of the rotating synchronous or asynchronous field.

AC motor speed is related to the frequency of the applied voltage and the number of magnetic poles while DC motor speed is related directly to the applied voltage.

In an asynchronous motor, the rotor rotates at the same speed as the stator’s rotating magnetic field. Whereas in an asynchronous motor, the speed of the rotor is slower than the stator’s rotating magnetic field.

However, we can use VFD to vary the speed in the asynchronous motor.

Applications of Servo Motors

Servo motors are used quite frequently in manufacturing industries. For their precise control of angular positions, they are widely used. These are some applications for your reference in which servo motors are used.

Robotics Arms: It is widely used in many industries such as Automobile, Pharmaceutical, Medical, etc. Servo motors are used for each angular movement in the robotics arm.

Cameras: In modern cameras, a servo motor is used to autofocus images.

Solar Panel: Servo motors are used to move the solar panel in the direction of the sun.

Antenna Positioning: Correct position is necessary to get the best signal from anywhere. Servo motors are the perfect mechanism to rotate the antenna in the best position for the best signal reception.

Automatic Doors: We have seen an automatic door opening/closing in the mall, grocery stores, hospitals, cinema theaters, etc. This automatic opening and closing are achieved by the servo motor.

RC Toys: Modern toys are great examples of servo motors. RC cars, airplanes, boats, and tiny robots have servo motors in them.

Printers: To print a magazine, newspaper and even in a simple paper, proper movement of the printing head is the primary requirement. Servo motor is perfect to achieve this operation smoothly and accurately.

Summary

I hope you like this article about servo motor. I hope to justify the answer to What is a servo motor? How does it work? Types and Application of servo motors.

If you like this blog then please share it with your friends and colleagues and please provide feedback about the blog in the comment section.

You can read articles about PLC

⇒ What is a Programmable Logic Controller? How does it work?

⇒ What is SCADA? Features of SCADA.

⇒ What is DCS? Advantages and Features of DCS.

⇒ Basics of Siemens PLC Programming Blocks.

Very good article, thank you for sharing,