Temperature measurement is a very important and crucial parameter in the industry. Sensors used to measure a temperature are not designed to withstand the harsh environments.

All temperature sensors such as RTD, Thermocouple, Thermisters, etc. are susceptible to damage from flow, pressure, corrosion, abrasion, turbulence, etc. This could damage the sensors as well as cause safety issues.

A thermowell serves as a protective tube between a temperature sensor and measuring environments or a process media. We can find thermowell often in the petrochemical industry, the oil and gas industry, refineries, etc.

Table of Contents

Purpose of Thermowell

Thermowell is mainly used to protect a temperature sensor against mechanical damage, corrosion, excessive pressure, material velocity, etc.

Thermowell does the protection job very well, in addition to this, thermowell also reduces operating costs by providing easier serviceability to the temperature sensor.

If you want to replace or remove the temperature sensor, thermowell provides easy access to the sensor. Thermowell stays where it is installed in the piping system or furnace wall etc, which means no downtime in the continuous process.

The life of the temperature sensor also increases using thermowell. The temperature sensor in the thermowell stays long-lasting.

What are the components of Thermowell?

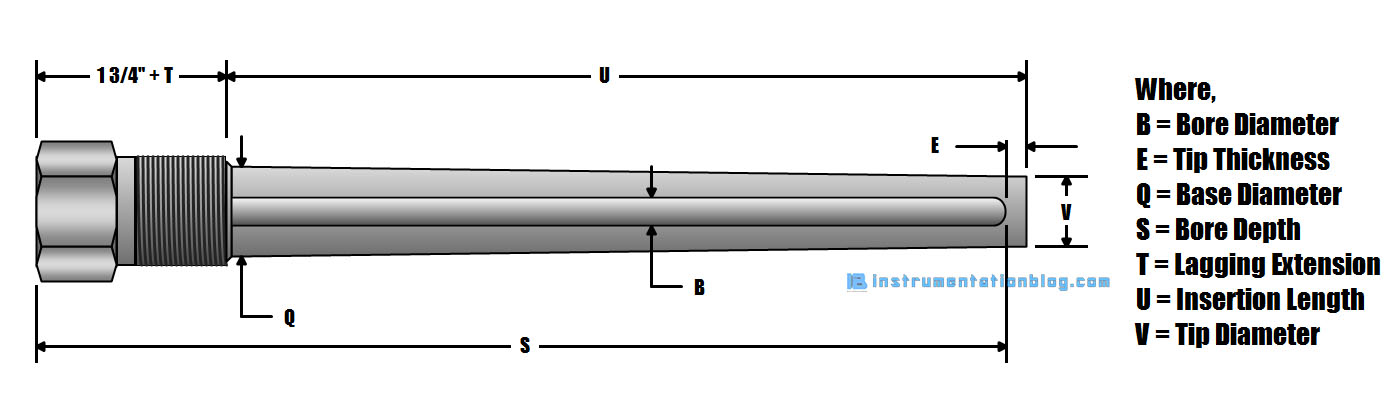

There are several components or specification which you need to know before choosing a thermowell, such as:

- Bore Diameter (B)

- Tip Thickness (E)

- Base Diameter (Q)

- Bore Depth (S)

- Lagging Extension (T)

- Insertion Length (U)

- Tip Diameter (V)

Bore Diameter (B)

Bore Diameter is the diameter of the thermowell where a temperature sensor is installed. This diameter must be the same or slightly greater than the outside diameter of the temperature sensor.

Insertion Length (U)

Thermowell insertion length (U) is the length, from the top of the thermowell to the bottom tip of the thermowell where it connects the process media.

To get the maximum accuracy, the insertion length must be long enough that touches the tip of the thermowell.

Legging Extension (T)

The legging extension is mainly referred to as the length of the cold-side of the thermowell.

Tip Thickness (E) and Tip Diameter (V)

Tip thickness is the bottom thickness of the thermowell and Tip Diameter is the bottom portion diameter of the thermowell.

Process Connection of Thermowell

Thermowell can be connected to an RTD, thermocouple, or thermister head through several different types of connection. Types of thermowells process connection such as,

⇒ Threaded

Threaded thermowell is directly screwed on the wall or pipes of process media. These types of thermowell are used mainly on smaller pipes to measure the temperature of the non-corrosive fluids.

⇒ Socket Weld

Socket weld thermowell is directly welded on the pipeline. It is used where a permanent connection is required.

⇒ Flanged

Flanged thermowell has a flanged collar, which is fitted using nuts and bolts to the process pipe or wall. Generally in this type, we can replace the whole thermowell whenever it is required.

Thermowell Shank Construction

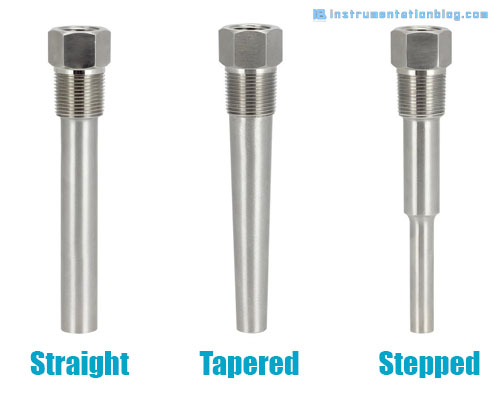

This is about the immersion portion of the thermowell. The most common types of shank constructions for thermowells are straight, stepped, and tapered.

Different shank construction for thermowell types are such as,

⇒ A straight shank type thermowell has the same size of outer diameter all along a thermowell.

⇒ A stepped shank type thermowell has a different size in outer diameter. Generally, in steps like we can find a smaller outer diameter of immersion, as we move to the bottom we find a smaller outer diameter.

⇒ A tapered shank thermowell has an outside diameter that gradually decreases all along the immersion length.

Materials of Thermowell

Choosing the right material is crucial for the long-life of the thermowell. The material of thermowell is exposed to the chemical, temperature, and material flow rate. The corrosive effects of the chemical are normally increased with an increase in temperature. Some of the most frequently used materials in the thermowells are:

- Carbon steels

- Chromium/molybdenum steels

- Socket weld

- Stainless steel

- Incoloy

- Inconel

- Monel

- Hastelloy

- Haynes Alloy

- Titanium

The most commonly used thermowell material is Stainless steel due to its cost-effectiveness and high resistant to heat and corrosion. Carbon steel is also a low resistant to corrosive substances.

What is the important information that is required while purchasing a thermowell?

When you purchase a thermowell for your application then you need to know about some important information, such as

⇒ Process connection size and types

⇒ Thermowell insertion length

⇒ Legging extension

⇒ Shank configuration

⇒ Bore length

⇒ Thermowell material

⇒ Process design temperature and pressure

Summary

Temperature sensors are susceptible to harsh environments such as excessive heat and pressure, flow rate, corrosion, vibration, etc. Over time it could lead to damage to the sensor as well as affect the process.

Thermowell protects the measuring sensor as well as increases the life of the temperature sensor. It also provides easy access to the sensors and reduces the service cost of the sensor.

This is all for the day about What is a Thermowell? and I hope you like this article. Share it with your friends and colleagues. Give your comments about the article in the comment section below.

Next Articles >>>

⇒ What is RTD? How to choose the best RTD as per your application?

⇒ Difference between 2-wire, 3-wire, and 4-wire RTD.

⇒ What is Thermocouple? Types of Thermocouples.

You can read more articles about Electrical and you can also find books that boost your knowledge in the field of Instrumentation ⇒

Thanks for reading!