Have you visited my previous blog about What is PLC? How does it work? Components, Applications, Advantages of PLC.

It’s very useful, Isn’t it? Please share it if you find it useful.

In this blog, we are going to cover a depth overview of SCADA Software.

SCADA is the short abbreviation of Supervisory Control and Data Acquisition.

As the name suggests SCADA mainly does three operations:

- Supervise real-time data in the form of graphical presentation

- Control industrial processes locally or through Remote locations

- Acquire real-time data as well as logs data

SCADA system is an important factor of the industrial organization as they help to monitor process data as well as control the processes and easily detect any issue within the process thus reduce downtime.

Let’s start the blog,

Table of Contents

What is SCADA Software?

SCADA is defined by Subnet Solutions,

“SCADA is an acronym for Supervisory Control and Data Acquisition. SCADA generally refers to an industrial computer system that monitors and controls a process.”

Basic Overview of SCADA Software

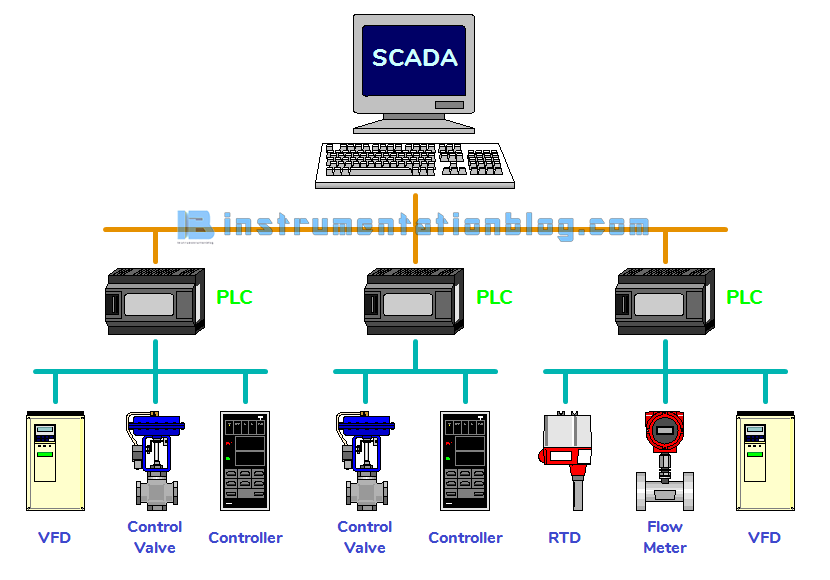

Generally, SCADA is completely a software package that helps to monitor the entire area of the plant. The basic architecture of the SCADA begins with a Programmable Logic Controller(PLC) or Remote Terminal Units(RTUs).

As we know, PLC or RTUs are microprocessors that communicate with the field devices such as valves, pumps, sensors, HMIs, other end devices, etc. These devices route all this collected data from end devices to SCADA computers.

Then SCADA software processes distribute and display the data on the monitor to better understand the operator about the field condition.

For example, In a cement plant, there are various weighing scales. The operator is allowed to change the specific set rate for each weighing scale according to plant requirements.

SCADA displays the real-time process value of each weighing feeder and also logs the data.

SCADA Architecture

Application of SCADA

Today, many industries use SCADA applications to monitor as well as control the industrial process, to maintain efficiency, to reduce breakdown time, and to analyze historical data.

SCADA systems are the backbone of the many modern industries like,

- Oil & Gas

- Energy

- Transportation

- Manufacturing

- Food and Beverage

- Power

- Wastewater treatment

SCADA Example

SCADA is running everywhere in a simple to complex format, as an example, we can see the energy usage of our home with the help of this, a quality standard can be achieved with the help of this software are some common examples.

History of SCADA

At the earliest generation, mainframe computers are used, at that time network is not evolved. Each SCADA system worked on its own.

If the mainframe system got failed, then there is another backup mainframe system that was there. This is called the monolithic SCADA system.

Later that in the 1980s and 1990s, the size of the computer became smaller. Thanks to Local Area Networking(LAN) technology and PC-based HMI software, SCADA was becoming popular.

Now they were connected with other SCADA systems. This system is called the Distributed SCADA system.

From the 1990s to the 2000s, SCADA has adopted an incremental change, SCADA began to implement open system architecture with a communication protocol that was not vendor-specific.

SCADA system allowed that different vendor systems now can communicate with each other. With the standard protocol such as Ethernet and internet access, the vulnerability of the system was also increased. But some standard security features also improved with time.

This system is called the Networked SCADA system.

By the late 1990s to the early 2000s, a rapid incremental occurs in IT technology. The structured query language(SQL) database became the default database.

SCADA developers didn’t implement this database and this results in the SCADA system became out of date in quickly growing technology.

Current Day

Modern SCADA systems have a great advantage over the older SCADA system with changing in technologies and adopting newer IT technology such as SQL and web-based applications, it is now possible to monitor real-time data from anywhere around the globe through the SCADA system.

It would be extremely difficult to gather real-time information without SCADA software. Modern SCADA software is rapidly improving and now it allows to design applications relatively easily, even if they don’t have knowledge of software development.

The modern IT standards, protocols, and web-based applications introduce in SCADA software, which greatly improved the efficiency, security, productivity, and reliability of SCADA systems.

Data analysis from SCADA software is greatly improved with the historical data logging using the SQL server in the SCADA application.

Features of SCADA System

1) Control Feature using Graphical Representation

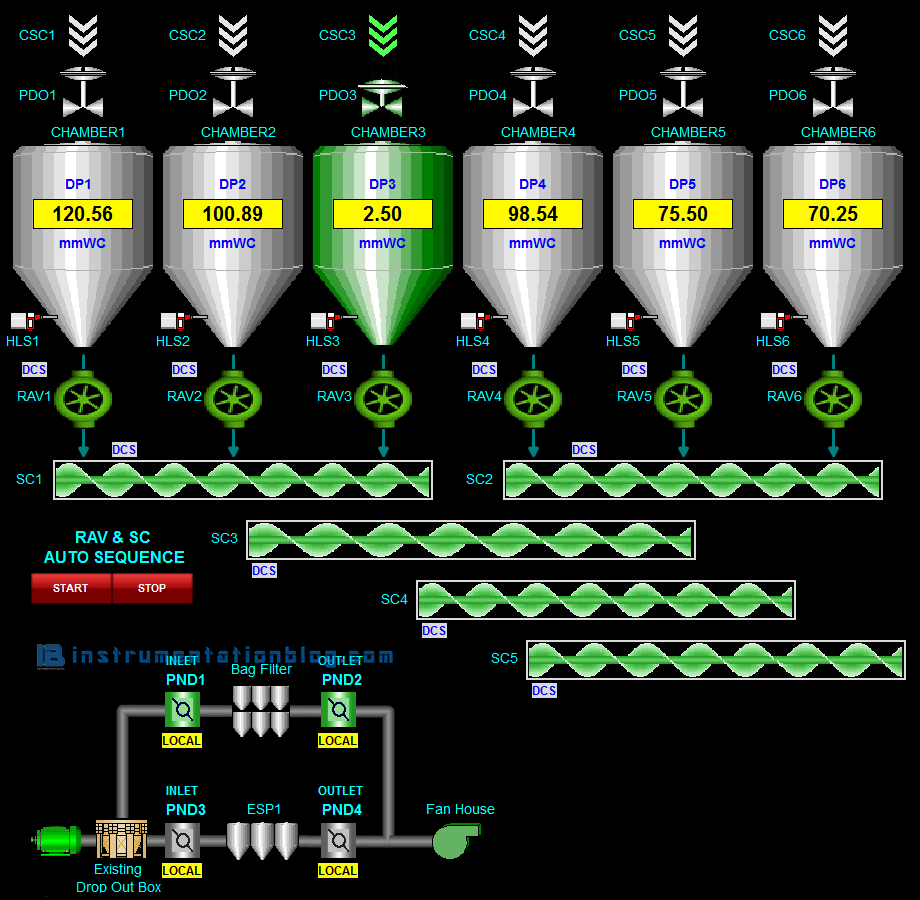

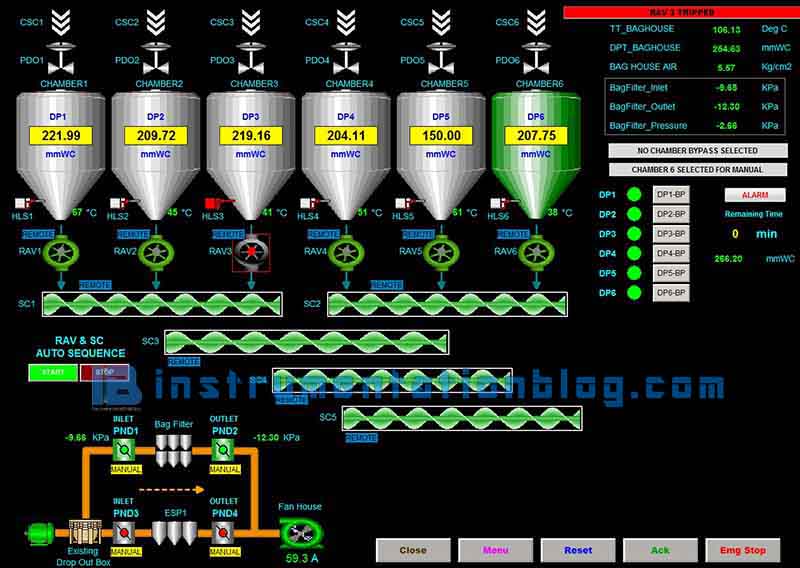

The main aim of the SCADA system is to establish the control of the different machines of ground level from the main control center. In an industrial process, it is necessary to start and stop a manufacturing or industrial sequence.

With the help of SCADA, the operator can start and stop the different industrial sequences from the control center as well as monitor the status of different equipment.

Monitoring and controlling equipment from a text-only interface are sometimes complicated. SCADA can graphically display control, it will become very easy to understand the status of any equipment.

SCADA Graphical Control Example

2) Real-time/Historical Trend Feature

The next useful feature of SCADA is Trend. Many times it is necessary for any industrial process that needs to be monitored as well as logged.

Trends are essential for any industrial automation system. SCADA system is capable to store real-time data from fields, retrieve historical data, and graphically present them.

SCADA Trend Management

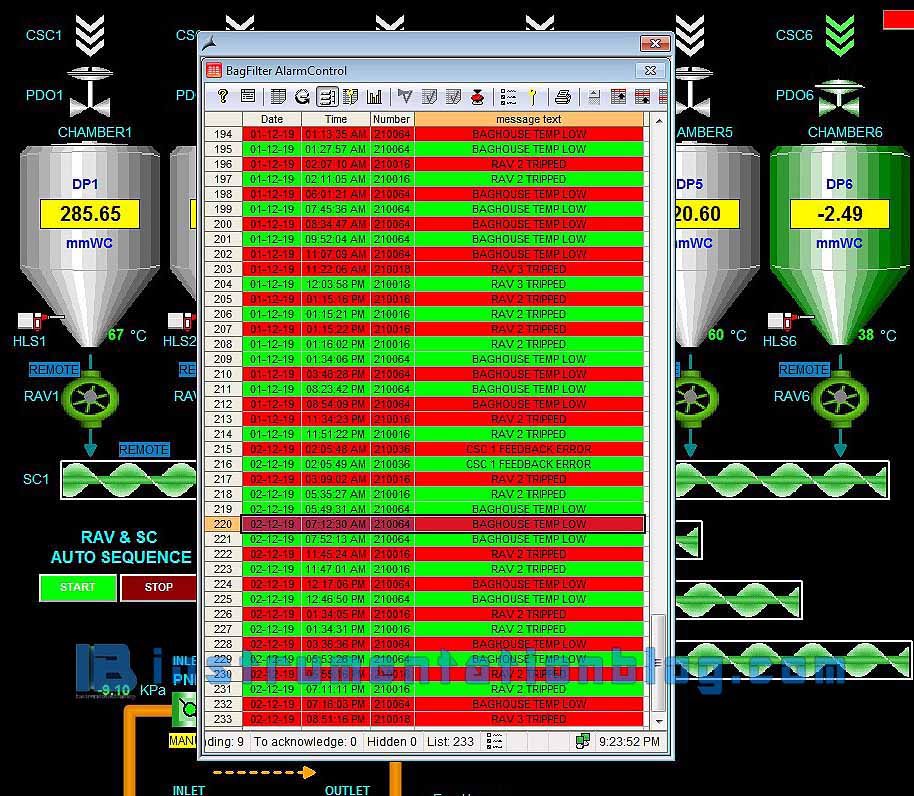

3) Alarm Handling

An alarm system is a system designed to direct the attention of the operator to significant aspects of the current state of the plant. SCADA can perform this task with high accuracy.

It can track deviation in the rate of change monitoring for analog values as well as a change in the digital input/output values. It can display historical alarms also.

SCADA Alarm Management

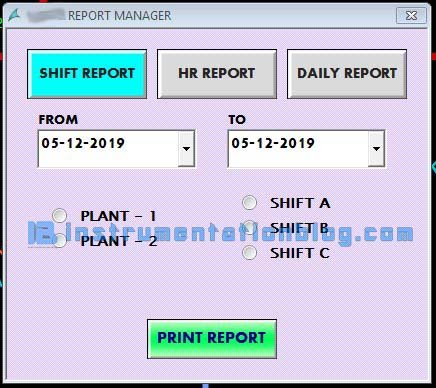

4) Report Generation

SCADA provides an amazing functionality – Report. The user has to prepare a format in which they want a report. The user can select an event that triggers a report. There is also the functionality that a user can generate a report manually at any time.

SCADA Report Management

Advantages of SCADA System

- Reduce Breakdown time by continuous monitoring of equipment status.

- Reduce manpower costs required for operating and monitoring equipment in different areas.

- Flexibility to give report generation in an auto manner as well as manual.

- Provide remote access to the real-time display, alarm, trend, and report generation.

- Provide flexibility to choose equipment and system based on performance.

Popular SCADA software brands

Some of the most common companies that provide SCADA systems, which are largely used in Industries:

- Siemens WinCC

- Allen Bradley RSView

- Invensys Wonderware Intouch

- GE Fanuc Simplicity

- Elipse E3 SCADA

Read next articles,

⇒ What is PLC? How does it work?

I want to study PLC Siemens S7 300/400

You can refer to the PLC series tutorial in this website.