Table of Contents

How does a Diaphragm Pressure Gauge work?

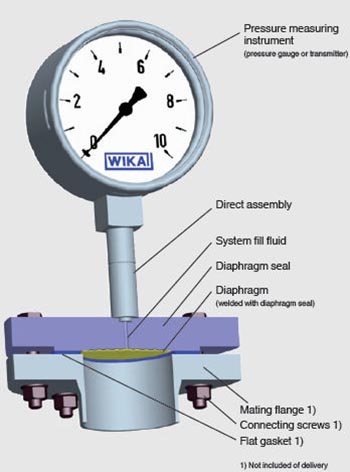

The diaphragm pressure gauge consists of a circular membrane, clamped between a pair of flange.

The positive or negative pressure acting on the diaphragm causes the deflection of the measuring element.

The magnitude of the deflection is proportional to the pressure being measured. The diaphragm pressure gauge is used to measure gases and liquids with a pressure range of 10 mbar to 60 bar.

Working principle of Diaphragm Pressure Gauge

The diaphragm is preferably suitable for the gauge, absolute, and differential pressure measurement. The diaphragm pressure gauge has a circular, corrugated diaphragm as the main element which is clamped or welded between a pair of the flange.

The diaphragm is generally manufactured from resilient steels such as stainless steel or Inconel. The deflection of the pressure element is transferred via a link or mechanism. This mechanism amplifies the small deflection of the element and transfers it to the pointer.

Image Credit: directindustry.com

The process pressure is applied to the lower side of the diaphragm and the upper side of the diaphragm is open to atmospheric pressure. The differential pressure across the diaphragm lifts up or down the diaphragm and puts the pointer in motion.

Which is better, a flat or a corrugated diaphragm?

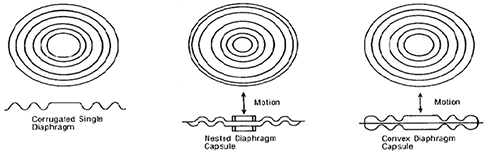

The deflection of the diaphragm must be linear, such that a similar increase in pressure with a similar deflection at each time. A flat diaphragm made up of metal will only be linear if the deflection is smaller.

The flat diaphragm loses its linearity at a larger deflection due to more and more stress occurs on the diaphragm and it will become stiffer.

For industrial application, a corrugated metal profile diaphragm is generally used. A corrugated diaphragm ensures linear deflection and is more elastic than the flat diaphragm.

Image Credit: greenishco.com

Diaphragm against corrosive media

The corrosive media can damage the diaphragm if it would not be accurately protected. The diaphragm of the diaphragm pressure gauge is usually glued with a foil of selected material to protect from the aggressive media.

In some cases, the entire diaphragm is made up of special material. This special material should meet the elasticity and sealing required for the measuring task.

Diaphragm pressure gauge is suitable for measuring the viscous, crystallizing, and contaminated media. Diaphragm pressure gauge with open connecting flange eliminates such problems.

For sensitive media such as the pharmaceutical and food industry, a flush diaphragm is mainly used. With such a design, it does not contain any dead space and it will easy to clean.

Pros and Cons of Diaphragm Pressure Gauge

Advantages

- Excellent load performance

- Linearity

- Suitable for measuring absolute and differential pressure

- Small in size

- Can be used to measure viscous and slurry materials

Disadvantages

- Seismic, impact-resistant is not good

- Difficulty in maintenance

- lower measurement pressure

You can read more articles about Electrical and you can also find books that boost your knowledge in the field of Instrumentation ⇒

Thanks for reading!